Products

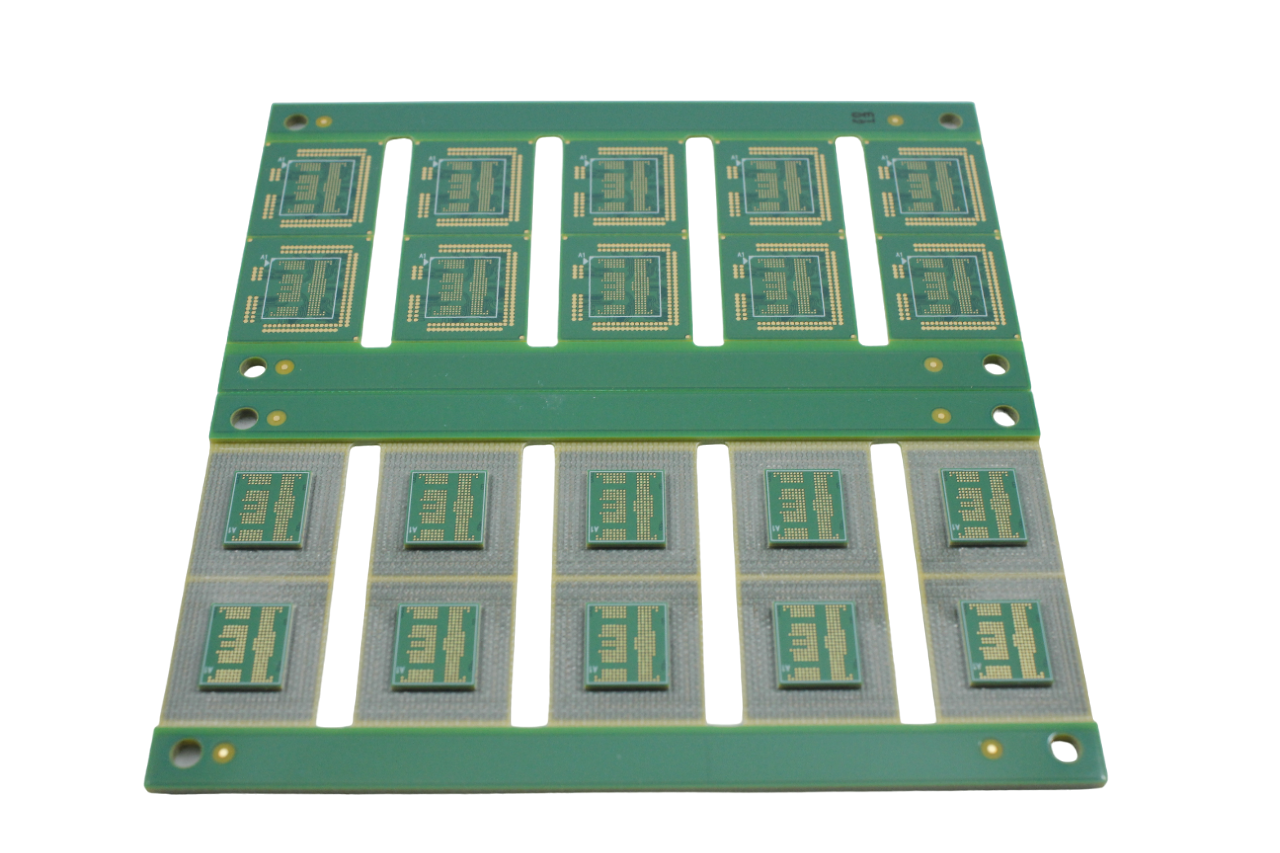

Rigid PCB

PCB, which stands for Printed Circuit Board, is often referred to as the "mother of electronic components." Its applications are quite extensive, primarily because it serves as the essential substrate for assembling electronic components, acting as the framework for electronic parts. It allows various components to connect and transmit signals and currents through the metal copper foil traces on the board. Currently, PCBs are mainly used in fields such as information technology, communications, consumer products, automotive, aerospace, industrial control, and military applications.

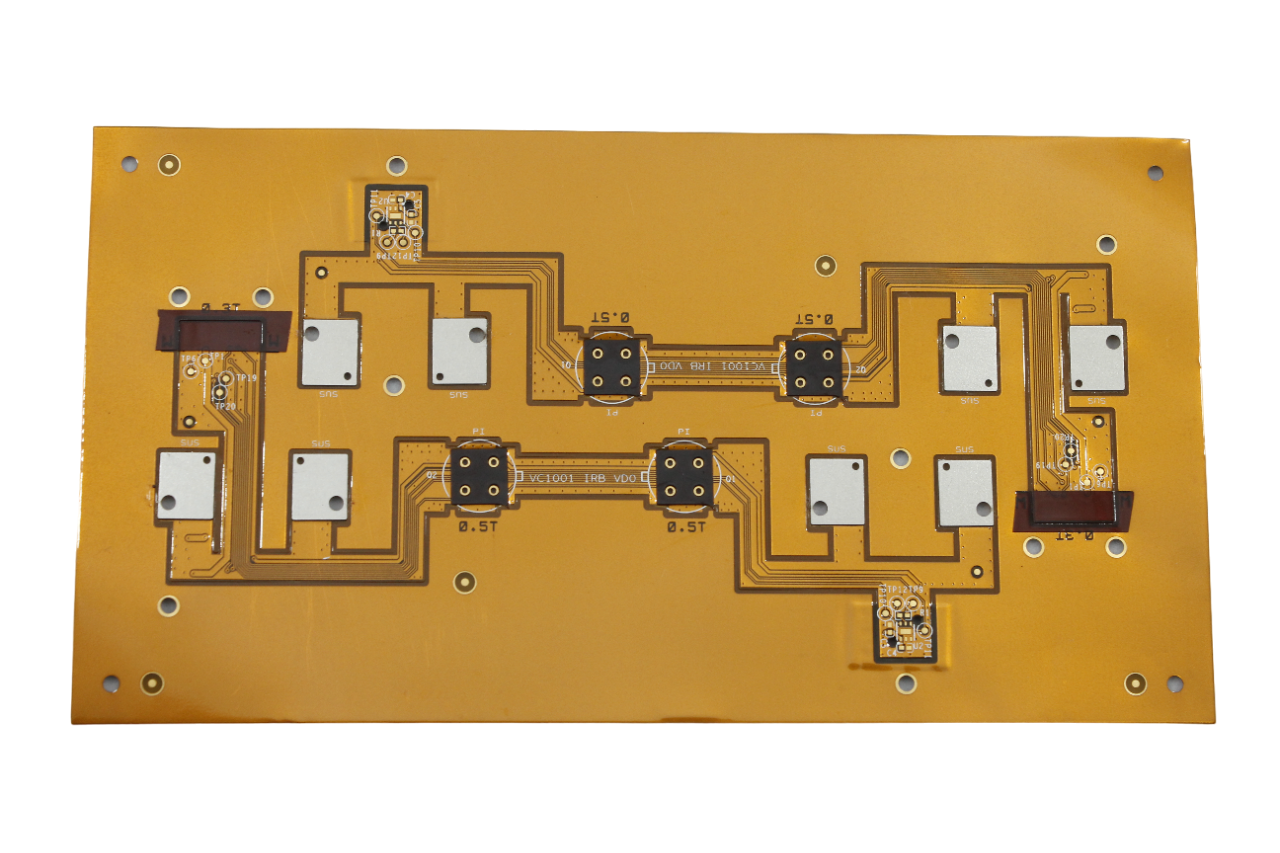

Flex PCB

Flexible PWB (Printed Wiring Board) is made from soft laminated plastic or other flexible insulating materials as the substrate. Parts made from it can be bent and stretched, allowing them to be flexed during use according to installation requirements. Flexible printed boards are typically used in special applications. For example, the display screens of some digital multimeters can rotate, and flexible printed boards are often used internally, such as in mobile phone displays, buttons, and other components.

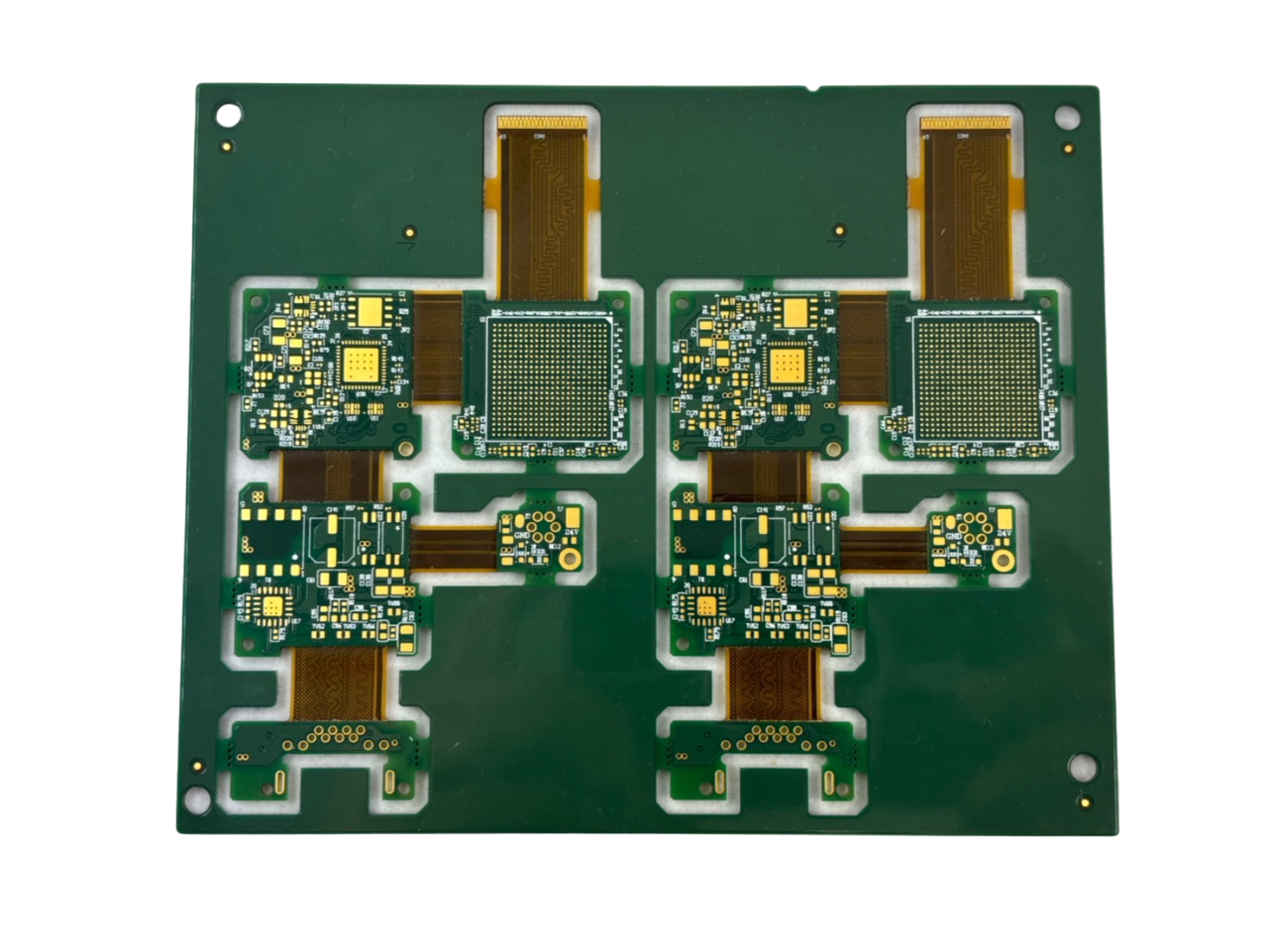

Rigid-Flex PCB

The birth and development of FPC (Flexible Printed Circuit) and PWB (Printed Wiring Board) have led to the creation of new products for both flexible and rigid boards. Therefore, a rigid-flex board is a combination of flexible and rigid circuit boards. After processes such as lamination, they are assembled together according to specific technical requirements to form an electronic board that has both FPC and PWB characteristics.

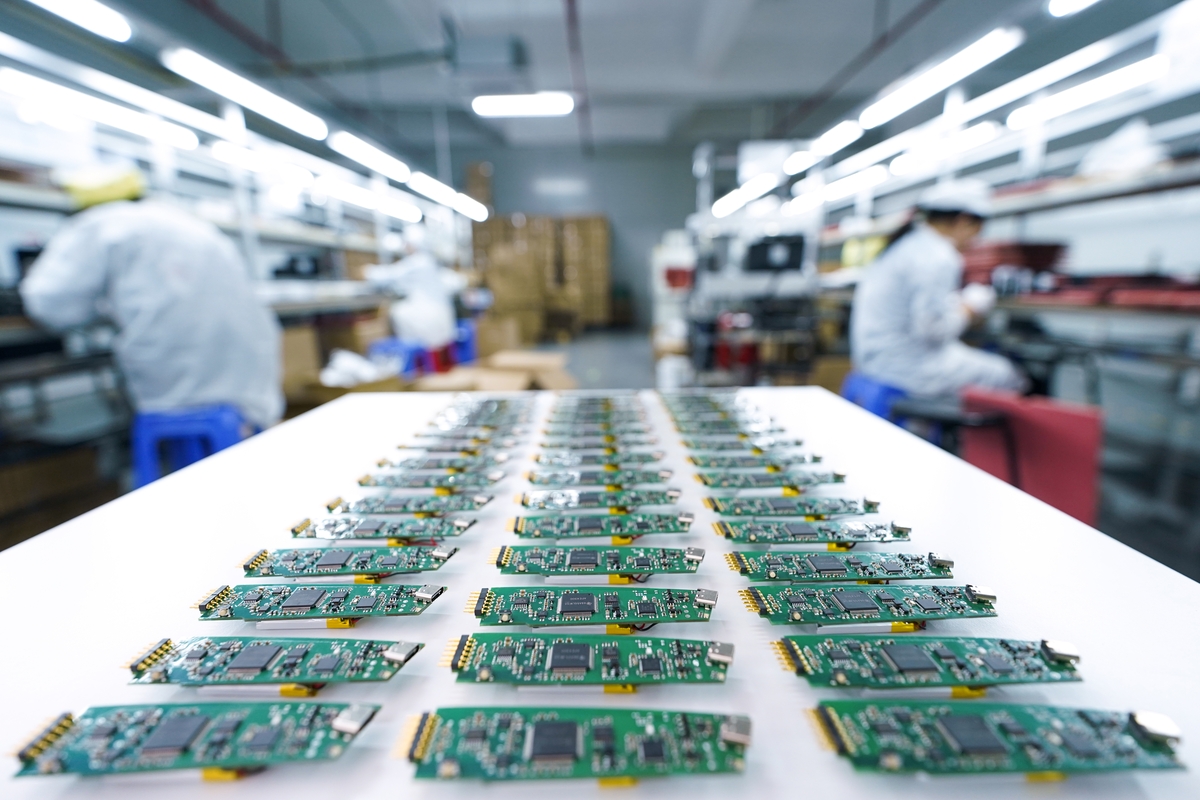

SMT Service

Surface Mount Technology, also known as SMT (Surface Mounting Technology), is a process where surface-mounted components are directly soldered onto specified positions on a printed circuit board (PCB) without the need to drill holes for through-hole mounting. Currently, SMT is widely used in the manufacturing of PCBA boards for electronic products, replacing traditional through-hole technology. SMT improves product reliability and performance while reducing production costs, leading to significant transformations in electronic products, both in consumer electronics and advanced industrial electronic product sectors.